Use a smartphone and barcode scanning to manage bill of materials inventory (parts, components and raw materials) on the shop floor in real time.

Record parts and materials receiving, automatically adjust parts and materials stock as you build assemblies based on BOM.

Bill of materials (BOM) helps you streamline the process of building assemblies - finished products consisting of the components, parts and raw materials. Once you created a bill of materials for your final products,

parts and materials stock adjustment can be done automatically as you record building of assemblies on the shop floor. You can always check how many assemblies you can build from the parts and material stock you have on hand,

and what do you need to order to build the specified number of assemblies. Create reminders and receive automatic alerts when BOM parts and materials stock is low and it is time to re-order.

>

>

BOM Parts & Materials Tracking

Bill Of Materials Parts And Components Tracking With Barcode Scanning

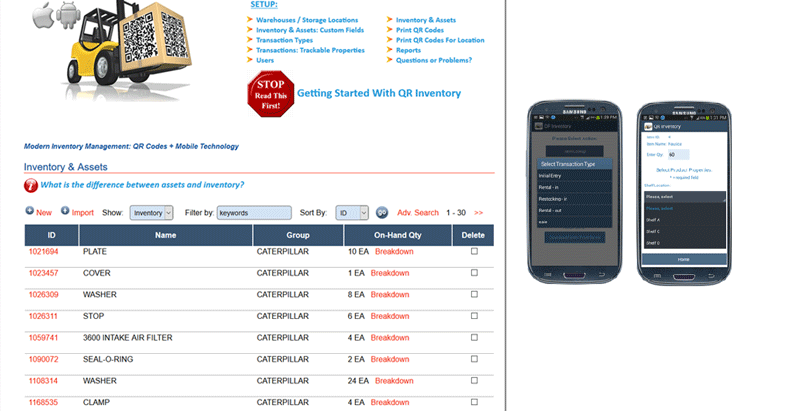

- Use smartphones for barcode scanning to record parts and materials inventory transactions on the shop floor in real time.

- Record all parts and materials transactions: receiving, storage, using in the assembly building, returning defective parts. Parts and materials stock is automatically adjusted as you

record inventory transactions.

- Save money on purchasing inventory tracking hardware, such as mobile computers and barcode scanners. Use regular smartphones for barcode scanning, data entry and look up.

- All parts and materials inventory transactions are stored in a secure cloud and are available for review by all authorized users via the web dashboard / reports.

Accurate Stock Control Of Parts And Materials For Assemblies Building

- Create bill of materials (BOM) for all final products / assemblies in an easy-to-use QR Inventory software web interface.

- Record building of assemblies, and parts and materials inventory stock will be adjusted automatically based on your bill of materials (BOM).

- Check real time parts and materials stock and storage location on the shop floor using mobile devices, and on the office computers via the web dashboard.

- Make sure you always have the right inventory stock on hand. Set minimum and maximum inventory level for the parts and materials,

and receive automatic low inventory alerts and suggested re-order quantity.

- Check how many assemblies you can build from the parts, components and raw materials you have on hand, based on your bill of materials.

- Create a list of the parts and materials that you need to order to build the specified number of assemblies.

Bill Of Materials Inventory Transactions Recording

- Adjust QR Inventory software to your business process.

Create custom transaction types that you need in your business to track parts, components, raw materials and building of assemblies.

- Define what additional information you want to collect when processing parts and materials inventory transactions. It can be anything, from PO number

for parts and materials to assembly building notes.

- You can track different custom parameters for the different transaction types.

- Capture images with a smartphone camera and attach to the inventory transaction for visual documentation.

- Obtain an employee or customer signature if required.

- Create a transaction receipt, that includes transaction data, captured signature and your company branding. View, print, e-mail pdf receipt from a smartphone.

Parts And Materials Inventory Stock & Transactions Reports

- Review reports on parts and materials inventory stock, locations, transaction history and usage.

- Filter reports by multiple parameters, including custom fields that you created.

- Export reports into .csv file for importing to other applications / software, or for sharing with the contractors / employees who do not have access to QR Inventory software.

- Review all files attached to the inventory transaction: image(s), signature, pdf receipt.