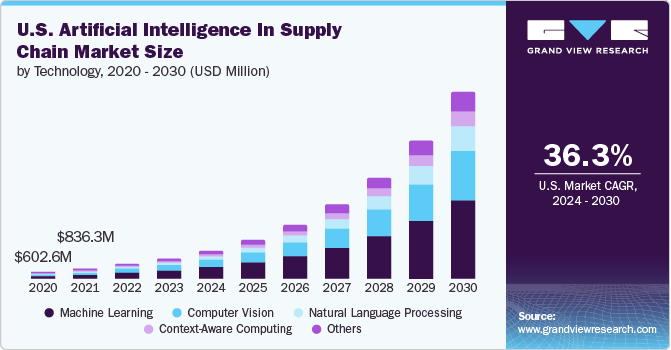

According to Grand View Research, the global artificial intelligence in supply chain market size was estimated at US$ 5.05 billion in 2023 and is projected to grow at a CAGR of 38.9% from 2024 to 2030. The SNS Insider report indicates slightly lower number. It found that the Artificial Intelligence in Supply Chain Market reached US$ 4.7 billion in 2023 and is expected to grow to US$ 89.4 billion by 2032, achieving a CAGR of 38.73% over the forecast period from 2024 to 2032. Whichever of these numbers is correct, it is clear that you ignore AI in Inventory management and supply chain at your own peril.

Introduction: What is Generative Artificial Intelligence (AI)?

Generative AI is a subset of Artificial Intelligence that creates new content after learning from the existing examples. It uses advanced machine learning models to generate output that mimics human creativity and existing data patterns.Generative AI approach is very similar to how you and I learn and create. Just like learning to cook by watching others and then, when you have a bit of experience, preparing your own dishes, these systems learn patterns from existing data and then create new, fully original content.

Examples Of Generative AI

Content Generation

A content generator (like ChatGPT, Claude, or Gemini) works like a very knowledgeable writer, who can create almost anything on your request. If you ask for "a story about a friendly dragon," it can create a completely new story by drawing from its understanding of how stories are structured, what dragons are, and the writing styles it learned from millions of other stories. It is not a copy and paste operation - the story created by the generative AI engine is new and unique, just like how people create new sentences using words they have learned before.Image Generation

There are several generative AI engines, such as DALL-E or Midjourney, which can generate completely new images based on the data they learned. You can think of it as having an artist at your command. You can type something like "Draw me a purple cat wearing sunglasses and riding a skateboard," and the system will create a brand new image matching your description. It has learned from millions of existing images what cats look like, what skateboards look like, and how to combine these elements in a way that makes sense - just like how a human artist might combine different things he had seen to create something new.

Generative AI Use In Business

Generating texts and images are common, "every day" examples, but this is not the only use of generative AI. Generative AI can be used in businesses of all types, creating predictive scenarios, generating synthetic data, and developing innovative solutions for complex challenges. It helps businesses with automating processes and smart, informed decision making.Generative AI is already transforming inventory management by enabling "Autonomous Inventory Systems". These are fully automated inventory systems that can make intelligent decisions without human intervention. This level of automation significantly improves efficiency and enhances supply chain resilience.

Generative AI For Supply Chain: Capabilities And Benefits

Let's review the capabilities and benefits of generative AI for automating supply chain and inventory management:Predictive Analytics and Forecasting

Generative AI Capabilities

Generative AI can analyze huge amounts of data, including historical data, market trends, and external factors. As a result you receive a highly accurate demand forecast. Along with the demand forecasting, AI models can simulate various future scenarios, such as economic slowdowns and recessions, supply chain disruptions, and changes in consumer preferences.Benefits of Demand Forecasting and AI-Based Simulations

Accurate demand forecasting allows you to maintain optimal inventory stock, avoiding over-stocking and stockouts. Simulations of market and supply chain trends allow you to develop contingency plans and make informed decisions.Inventory Optimization and Replenishment

Generative AI Capabilities

Generative AI can continuously monitor your business vitals such as inventory levels, sales data, and supplier performance. It helps you identify optimal stock levels and automate inventory re-ordering. Inventory systems powered by the generative AI engine can generate purchase orders and trigger reorders without any human input.Benefits Of Inventory Level Optimization And Automated Replenishment

Generative AI engine allows you to maintain optimal inventory stock that is automatically adjusted based on the current projects and demand. AI-powered inventory system ensures that you always have required inventory in stock, but do not over-order, and requires little human oversight.Warehouse Layout Optimization

Generative AI Capabilities

Generative AI model can analyze order patterns, inventory turnover rates, and product groupings to suggest the best placement of items. AI predicts how frequently products will be picked or replenished and generates layouts to minimize travel time for workers or robots. Based on this info, the model can create warehouse layout options that maximize storage capacity and improve accessibility.The system aligns layout design with the picking strategies to reduce walking distances and streamline the flow of goods from picking to dispatch, generating efficient routes for the robots to follow.

In addition, a generative AI engine can simulate different layout configurations under various demand scenarios, such as peak seasons or new product launches.

Benefits Of Optimizing Warehouse Layout

Optimized warehouse layout increases storage capacity without the need for expansion, resulting in significant storage cost savings. Optimal layout and picking routes lead to faster fulfillment and reduced labor cost.Supply Chain Optimization

Generative AI Capabilities

Generative AI can identify disruptions and bottlenecks in the supply chain in real-time by constantly analyzing data. If disruption is detected, AI powered inventory system will generate alternative plans, or put into action one of the pre-approved plans to optimize the flow of goods. A big part of these plans is collaboration between different stakeholders in the supply chain: suppliers, manufacturers, logistics companies, and retailers. Cooperation between all parts of the supply chain improves information sharing and coordination, and, therefore, leads to better results.Benefits Of Supply Chain Optimization

Early detection of supply chain disruptions and bottlenecks allows businesses to address issues before they escalate, minimizing operational delays.Generative AI Case Studies: Real World Examples Of AI Applications In Inventory Management

Shein's AI-Driven Inventory Management

Shein is a leading online fast fashion retailer. It utilizes generative AI to rapidly adjust its supply chain in response to customer demands. By analyzing large amounts of data, AI helps the company predict trends and manage inventory efficiently, listing up to 600,000 items for a global market.This AI-driven approach reduces inventory waste and operational costs by accurately forecasting demand and optimizing stock levels. However, it's important to note that Shein has faced scrutiny over environmental and ethical practices, highlighting the need for responsible AI implementation.

Must Have Ideas' AI-Powered TV Shopping Channel

Must Have Ideas is an online retailer specializing in cleaning and homeware products. The company launched an AI-driven TV shopping channel on Sky, utilizing proprietary software named Spark. This system automates content scheduling based on stock levels and external factors, ensuring optimal inventory management and customer engagement.This AI-directed programming operates 24/7, significantly reducing operational costs and increasing sales. This innovation has attracted a loyal customer base and demonstrates how AI can streamline inventory management and marketing efforts.

Domino's UK & Ireland's AI-Enhanced Demand Forecasting

Domino's Pizza UK & Ireland is a major player in the food delivery industry. The company implemented generative AI and analytics through Microsoft Dynamics 365 to automate demand forecasting processes. The AI system analyzes historical sales data, local events, weather patterns, and economic indicators to generate precise demand forecasts.This AI-driven approach has improved forecasting quality, ensuring great customer experiences and timely product delivery. By automating the forecasting process, Domino's has enhanced inventory management, reducing waste and ensuring product availability.