Discover proven strategies to prevent inventory shrinkage and safeguard your profits. This comprehensive guide covers theft prevention, loss reduction techniques, and technology solutions to protect your business.

Inventory shrinkage is a critical issue for businesses of all sizes, affecting the bottom line and operational efficiency. Whether you manage a small shop or a large warehouse, preventing inventory shrinkage should be a top priority. In this comprehensive guide, we'll delve into theft prevention, damage control, and loss prevention strategies to help you safeguard your inventory. At AHG, we specialize in inventory management systems designed to optimize your operations and minimize shrinkage.

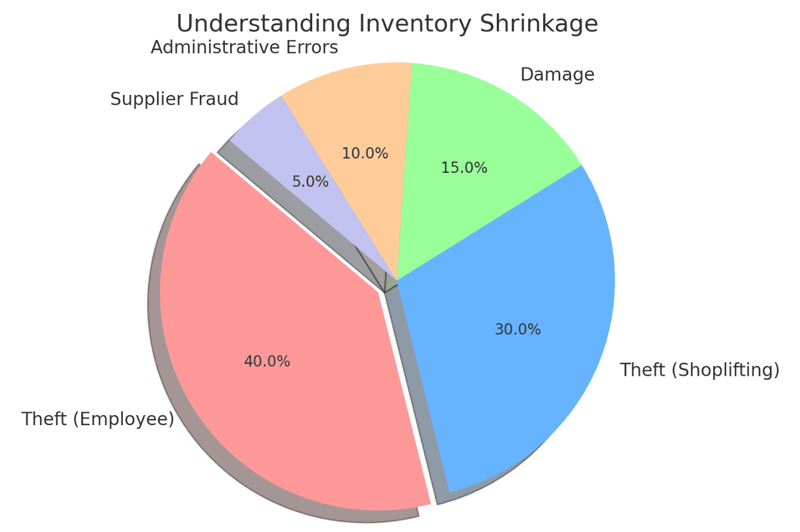

Understanding Inventory Shrinkage

Inventory shrinkage occurs when the actual inventory levels are lower than the recorded levels. This discrepancy can result from several factors, including theft, damage, administrative errors, and supplier fraud. Understanding the root causes is the first step toward effective prevention. Here are the strategies that will help you minimize and prevent inventory shrinkage.

Preventing Inventory Shrinkage

Inventory shrinkage is a persistent challenge for businesses of all sizes, but it doesn't have to be an inevitable loss. By understanding the common causes and implementing proactive strategies, you can significantly reduce shrinkage and protect your profits. Here are the key areas where you can make a difference.Prevent Inventory Theft

Theft, both internal and external, can significantly impact your bottom line. Let's explore strategies to deter employee theft and minimize losses from shoplifting.Employee Theft

Preventing employee theft requires a multifaceted approach, encompassing both proactive and reactive measures.- Background Checks Thorough background checks during hiring can help identify potential risks.

- Security Measures Implement security cameras, access control systems, and regular audits to monitor employee activity.

- Positive Work Environment Foster a culture of trust and respect to minimize the likelihood of internal theft. Encourage open communication and establish anonymous reporting channels for employees to report suspected theft.

Shoplifting

While focusing on internal security, it's equally important to address external threats like shoplifting, which can be mitigated through a combination of environmental design, technology, and staff training. Here is what you can do to minimize shoplifting:- Store Layout Optimization Design your store / shop / warehouse layout to minimize blind spots and enhance visibility for staff.

- Electronic Article Surveillance (EAS) Deploy EAS systems to deter and detect shoplifting attempts.

- Staff Training Educate employees on recognizing suspicious behavior and how to handle potential thieves professionally.

Inventory Damage Control

Even with the best prevention efforts, accidents can happen. It's crucial to implement damage control strategies to minimize losses from damaged inventory.Proper Handling and Storage

Proper handling and storage practices are essential for preventing damage and preserving the quality of your inventory.- Employee Training Thorough training on proper handling techniques can significantly reduce damage during inventory movement and storage.

- Adequate Storage Utilize appropriate shelving, bins, and packaging materials to protect items.

- Regular Maintenance Ensure that storage equipment and facilities are well-maintained to prevent accidents and product damage.

- Temperature and Humidity Control Real time temperature and humidity monitoring system helps you prevent spoilage and waste of perishable goods.

Quality Control

Maintaining strict quality control measures can help you catch damaging conditions early on, allowing for quick resolution and minimizing losses.- Regular Inspections Conduct routine inspections to identify and address problems that can lead to damaged goods promptly.

- Quality Standards Establish clear quality standards for incoming goods and ensure adherence by all employees.

- Supplier Audits Regular supplier audits can help maintain consistent quality and prevent the receipt of damaged goods.

Inventory Loss Prevention Strategies

Inventory Management System

A robust inventory management system is essential for preventing inventory shrinkage. Look for the following features in your inventory software:- Real-Time Inventory Tracking Monitor inventory levels in real-time to identify discrepancies quickly.

- Automated Reordering Set reorder points and reorder quantities at the company, warehouse, or even service truck level to maintain optimal stock levels and prevent stockouts or overstock situations.

- Comprehensive Reporting Generate detailed reports to analyze trends, identify potential issues, and make data-driven decisions.

AHG's QR Inventory system offers all these features and much more to help you keep inventory under control, prevent shrinkage, shortages and losses.

Regular Inventory Audits

Regular inventory audits play a pivotal role in identifying discrepancies, tracking trends, and maintaining accurate inventory records, all of which are crucial in the fight against shrinkage. Here are inventory audit methods you can implement:- Cycle Counts Implement cycle counting to regularly verify inventory levels without disrupting operations.

- Physical Counts Perform full physical count annually for thorough inventory reconciliation.

- Random Spot Checks Supplement regular audits with random checks to deter shrinkage and identify discrepancies.

AHG's QR Audit software allows you to perform both planned and ad-hoc audits fast and error-free using barcode or QR code scanning.

Employee Training and Awareness

Employee education and engagement are crucial components of a successful inventory shrinkage prevention program.- Regular Training Provide ongoing training on inventory management best practices and loss prevention techniques.

- Incentives Consider offering incentives for maintaining accurate inventory records.

- Awareness Campaigns Foster a culture of awareness and responsibility among employees regarding inventory shrinkage.

Conclusions

Preventing inventory shrinkage requires a multifaceted approach encompassing theft prevention, damage control, and robust loss prevention strategies. Implementing these best practices and leveraging AHG's advanced inventory management solutions, such as QR Inventory and QR Audit, can help you safeguard your inventory, optimize operations, and protect your bottom line.Contact us today to discover how our comprehensive inventory management systems can help you achieve your business goals and mitigate the risks of inventory shrinkage.