Tired of costly construction equipment downtime? Learn how asset management software like AHG QR Inventory can help you proactively manage your equipment, prevent breakdowns, and boost your project's profitability. Discover the power of real-time asset tracking, streamlined maintenance, and data-driven insights to optimize your operations. Say goodbye to delays and lost revenue, and hello to a more efficient and profitable construction business.

Picture this: you're in the middle of a major construction project, the deadline is looming, and suddenly, the excavator grinds to a halt. A crucial part has failed, and there's no replacement on site. The entire project screeches to a standstill, workers are idle, and costs are piling up faster than you can say "change order."

If this sounds familiar, you're not alone. A shocking 82% of companies have experienced at least one unplanned downtime incident in the past three years, and the construction industry is no exception. According to Milwaukee Tool, construction companies typically face a daunting 20-30% unplanned downtime for each piece of heavy equipment. It does not need to be a piece of heavy machinery. If one of 2 ROCUT circular saws broke, you just lost 50% of your productivity. If you can’t find one out of 2 jack hammers you can swear was on site yesterday, your day promises to be tough.

The frustration, delays, and financial losses caused by equipment breakdowns and misplaced tools can feel like an unavoidable part of the job. But what if we told you there's a better way? What if you could proactively minimize downtime, streamline asset tracking, and boost your bottom line?

The Hidden Costs of Downtime

Downtime's impact extends far beyond the immediate loss of productivity. Every hour a piece of equipment sits idle translates to:- Lost revenue: Missed deadlines, project delays, and potential penalties.

- Increased labor costs: Idle workers still need to be paid, even when they can't work.

- Rental expenses: If you need to rent replacement equipment, those costs add up quickly.

- Damaged client relationships: Delays and disruptions can erode trust and lead to dissatisfaction.

Industry estimates suggest that equipment downtime can cost construction companies thousands of dollars per hour. Imagine the savings potential if you could reduce those losses by even a small percentage!

The Asset Management Solution: AHG QR Inventory

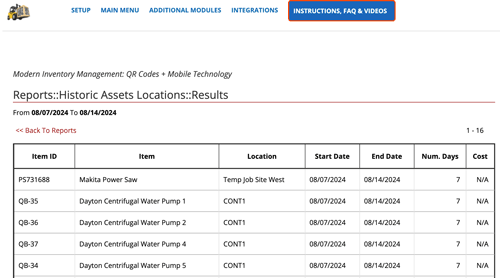

Enter AHG QR Inventory, the cutting-edge inventory and asset management software that puts you back in control. With real-time visibility into the location, condition, and maintenance history of all your equipment and tools, you'll never be caught off guard again.Need to locate a specific tool on a sprawling job site? Any employee can simply scan a QR code with their smartphone or tablet to instantly access its location, usage history, and maintenance records. No more frantic searching or wasted time!

AHG QR Inventory empowers you to:

- Schedule preventive maintenance Stay ahead of breakdowns by ensuring equipment is serviced on time.

- Receive automated alerts Get timely reminders for upcoming maintenance or any issues identified during inspections.

- Track equipment usage Optimize asset allocation and identify underutilized equipment to make informed purchasing decisions.

- Manage work orders efficiently Streamline maintenance requests and track repairs from start to finish.

QR Codes & BLE Tags: The Dynamic Duo

AHG QR Inventory harnesses the power of QR codes and BLE tags to deliver unmatched asset tracking capabilities.QR Code Asset Tracking

- Easy to create and attach to assets.

- Quick scanning with a smartphone or tablet provides instant access to asset information, real time tracking and updates.

- Efficient low cost solution.

BLE Asset Tracking

Case Studies & Testimonials

We used to spend hours searching for misplaced tools. Now, with AHG QR Inventory, we can locate anything in seconds. It's a game-changer!

- José G., Construction Foreman

Our equipment downtime has been cut in half since implementing AHG QR Inventory. It's paid for itself many times over!

- Dan M., Construction Project Manager

Take Control of Your Assets, Minimize Downtime, and Boost Profits

Construction equipment downtime is a costly challenge, but it doesn't have to be your reality. Embrace the power of asset management software, QR codes, and BLE technology to take control of your equipment, minimize downtime, and achieve new levels of efficiency and profitability.AHG QR Inventory gives you the tools to proactively manage your assets, streamline maintenance, and keep your projects on track.

Ready to see the difference? Contact us for a free, no-obligation consultation today and discover how AHG QR Inventory can optimize your business operations.